We have been designing technical components and articles in rubber and plastic on commission for all industrial sectors for over 30 years: this is why we understand the main requirements requested in this sector: articles must be effective and functional, long-lasting, easy to install and cheap. Our huge experience allows us to achieve the best solutions for each sector of competence, providing technical solutions which lead to excellent component efficiency, both from a performance and economical point of view.

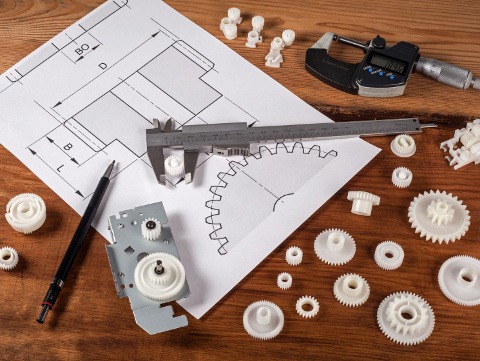

When the technical articles to be designed are for installation in complex mechanical systems, we carry out feasibility studies and structural FEM (finite element method) analysis which gives us useful information on any deformation, stress or movements which may occur on plastic components so as to optimize engineering of the pieces. Whenever our reference is an object which already exists, we apply reverse engineering to digitalize physical objects so that the geometric surfaces can be analysed and remodelled on a computer.

In collaboration with the client we define the products’ project specifications (economic, dimensional, mechanical, technical and aesthetic) in observance of the required standards: EC ISO, UNI, IP. All those technical and functional aspects of the product are taken into consideration (operating requirements, mechanical loads, contact with specific substances, assembly or installation systems…) with the aim of providing an executive three-dimensional file which corresponds exactly with the project and can be used immediately to engineer the mould.