THE CHALLENGE

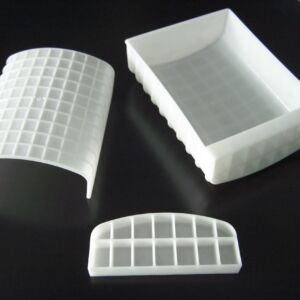

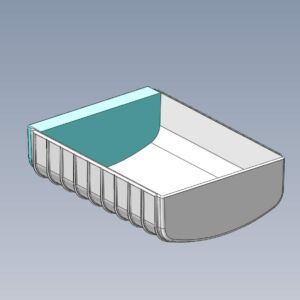

These moulds are used to shape hams and other cured meats between bone removal and sale of the product to the purchaser. Basically, the ham cut, once it has been boned, is pressed by special machinery and vacuum packed. The use of a mould (usually made from metal) is needed to support and contain the pressed meat so that over time it does not lose its shape which would make subsequent slicing problematic, often resulting in the wastage of quality meat during the slicing process.

The challenge we were given by a number of ham processing and boning companies in the Parma food district was to find an alternative solution to the use of steel moulds in order to achieve savings in the production cycle.

PlastDesignStudio took up the challenge to study and assess the feasibility of making plastic ham moulds in order to create a cheaper alternative to metal moulds while still being just as effective.

THE SOLUTION

Engineering

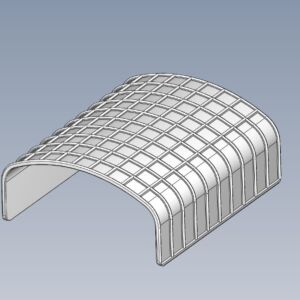

PlasDesignStudio started with the structural analysis of the metal mould to understand the technical and mechanical characteristics we would have to keep in switching from one type of construction material to another. We identified several aspects concerning flexibility, mechanical strength, hygiene and resistance to low temperatures (once boned the block of ham is placed in its mould and stored in freezers at subzero temperatures).

The FEM analysis, by simulating mould use in standard conditions, provided us with data which helped us to identify and prevent any deformation or fragility of the article and this meant we were able to identify the most suitable material for its production: HDPE, a food-contact polymer certified by the FDA with a low friction coefficient which is flexible but at the same time stronger than standard PE and is cheap to buy, thus further increasing savings in production costs.

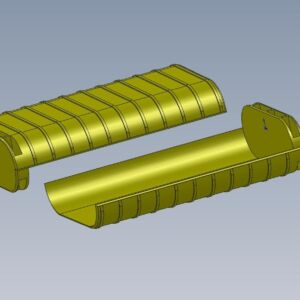

Based on these indications our engineers developed the 3D mathematics of the piece, designing a made to measure mould to suit the size of the ham cuts used by the client company ensuring, therefore, a perfect fit.

Mould engineering and construction

Once the three-dimensional executive files were approved, the industrialization process continued with the engineering and making of the injection mould in collaboration with Csplast.

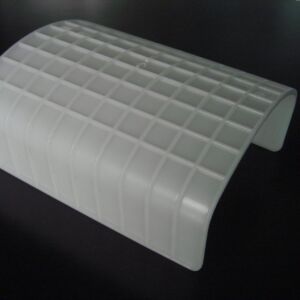

RESULT

Thanks to redesigning the ham moulds in plastic we were able to provide our client with the following benefits:

- Optimization of slicing the block of ham thanks to the continuous and constant traction exerted by the mould which prevented any wrinkling or loss of shape;

- Reductions in production costs, which make it possible to easily offset any costs for moulds not returned to the deboning plant;

- Lighter moulds making handling of the ham blocks much easier;

- Made in atoxic, FDA certified food-contact plastic;

- Washability of the mould so it can be reused;

- Production of ham blocks in the shape and size required by the client.