Technologies for moulding plastic: thermoforming or injection?

PlastDesignStudio is specialized in design, engineering and realization of products with two main technologies for moulding plastic: injection moulding and sheet thermoforming.

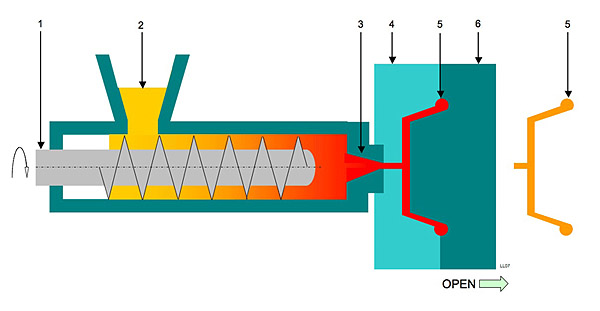

Injection moulding

The most widely used method for mass producing plastic objects is injection moulding. This is done using special presses which melt the plastic granules and inject it at high speed and pressure into the moulds where the polymer cools and hardens to the required shape. Injection moulding is used to process both thermoplastics and thermosetting polymers.

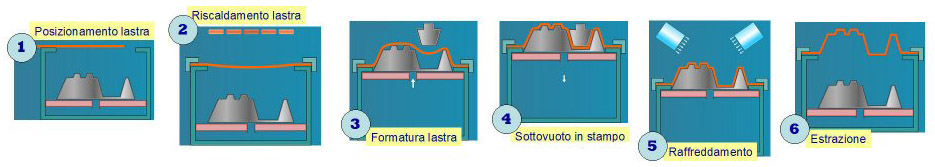

Sheet thermoforming

Thermoforming is a technique used for moulding heated plastic sheets. The product is created by moulding a sheet of pre-heated plastic over an aluminium mould. The plastic sheet, heated to make it pliable, is inflated like a balloon over the mould then, thanks to a strong vacuum created between the surface of the mould and the plastic sheet, it is laid over the mould where it replicates its shape and geometry. The strong points of sheet thermoforming, one of the solutions we offer our clients, lies in its production simplicity and the low investments needed for mass production

OPTING FOR INJECTIONMOULDING BECOMES ESSENTIAL WHEN A PRODUCT HAS TO BE MANUFACTURED ON A VERY LARGE SCALE. IN FACT, THIS IS THE ONLY WAY TO REDUCE COSTS AND IMPROVE THE QUALITY AND AESTHETICS OF THE PRODUCT, ENSURING THE MANUFACTURING COMPANY UPHOLDS AN IMAGE OF MAXIMUM